18. April 2017

Productive stripping process. With the marbastrip technology.

Marbach has relied on dynamic stripping with the marbastrip technology for many years. Up to now more than half a million stripping tools in this version have already been sold.

The topic stripping plays an important role in the die-cutting process. Marbach developer Sascha Wormser: “A team can only be as strong as its weakest part. This also applies to the production process of packaging. The die-cutting or blanking stations are rarely the limiting factor. In most cases it is the stripping section. With efficient stripping tools – that ensure almost 100% waste-free blanks and therefore high production speed in stripping – the entire process can maximize machine speeds.”

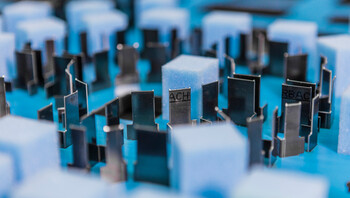

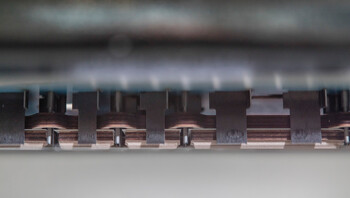

Marbach had already recognized this problem in the 90s and introduced at that time onto the market its revolutionary dynamic stripping technology: marbastrip. During stripping with marbastrip, specially produced stripping claws make sure that the waste is pressed through the female stripper. Support surfaces in the female stripper ensure that the stripped part can’t be pushed back to the top, but dynamically ejected from the stripping tool.

With this technology, Marbach has set a standard that is and will continue to be valid into the future. Because today marbastrip forms the basis for the Marbach stripping system masterstrip|plate. It’s male stripper is equipped with a presser plate and special lifter. The presser plate in the male tool makes sure the waste is evenly fixed during the stripping process. The sheet lifter marbafly supports the smooth transport of the paperboard sheet. A perfect system in combination with the marbastrip technology. Moreover Marbach has developed the precision set-up support marbapoint for setting up the stripping tool in the die-cutting machine. Male and female strippers can be quickly and perfectly positioned with the help of a specially calibrated laser beam.

Wormser continues: “Maximum machine speeds are possible with our stripping technologies. marbastrip is a fully developed and mature technology. marbastrip claws form the basis of the marbastrip technology. These are tested million of times and meet all functional requirements. The original is only available at Marbach. marbastrip claws and the special supporting technology build a homogeneous team for stable and secure stripping processes.”

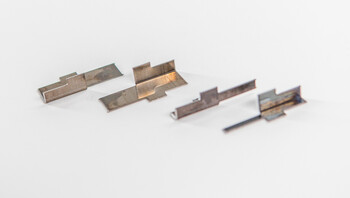

The advantages of marbastrip claws are manifold: They are suitable for stripping paperboard as well as corrugated board and can be placed very close to one another in the tool. The Marbach claws have a hardened tip. This makes them especially sharp and ensures a long tool life span. The quality of the claws is mainly responsible for the smooth dynamic stripping process. The Marbach claws can be positioned very accurately thanks to their design. Their 90° bend provides high stability. For this reason the claws cannot tilt or shift during the production process. And they press exactly on the spot where they are needed for optimally stripping the waste. The notch of the marbstrip claws leads to optimal height positioning and prevents any push through of the claws towards the back of the upper part.

During the last years machine set crown pins came into fashion. Wormser: “Crown pins have become established. We also use them. Used carefully on defined spots in the tool they optimally complement the functionality of marbastrip claws. Not more. And not less.”

The Marbach stripping technologies marbastrip and masterstrip|plate together with the original marbastrip claws will continue to serve as the basis for a fast and smooth stripping process in the future.