15. February 2018

Corrugated board die-cutting at high-speed. Marbach tools "marbaspeed" with flexpower rubbering on the road to success.

For several months now Marbach has been equipping its premium tools marbaspeed, for flat die-cutting, and marbaspeed|r, for rotary die-cutting, with its new special rubber flexpower. This new type of rubbering stands for durability and best die-cutting performance. Statistics show the extent of its success: Marbach sold more than 2,000 rotary dies for corrugated board alone in the marbaspeed|r version.

Sales Manager Silvio Gruber: "The sales success of marbaspeed shows us that the decision to use flexpower as a standard rubbering for our marbaspeed tools was absolutely right. Because this rubber is not only more durable than conventional high-tech rubbers, but also possesses ideal technical characteristics that enable the highest speeds in the die-cutting process. It's a perfect match for our premium tools marbaspeed and marbaspeed|r."

The new type of structure allows flexpower to be compressed more than conventional rubbers. This has clear advantages for die-cutting quality. In addition, flexpower's high rebound elasticity means that waste is ejected quickly and efficiently during rotary die-cutting. This results in high machine speeds and waste-free operation.

Due to its technical characteristics flexpower ensures very good die-cutting quality and smooth production processes with high speeds in flat die-cutting.

Gruber continues: "In the rotary sector, our customers have recognized that marbaspeed|r is the perfect tool solution for orders with high demands. In the flat area we are not quite as far yet, but still, here too there is a strongly increasing trend and more and more tools in marbaspeed design are being used."

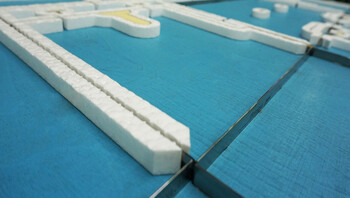

Not only the technical properties of the flexpower rubbering make marbaspeed tools special. But also their appearance. Due to the white color of the rubbering and its special structure, marbaspeed tools can be recognized at a glance.