die-cutting technology

Thermoforming

28. October 2020

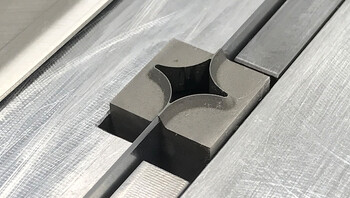

Tools for cold cut packaging.

Marbach has recently extended its portfolio. From now on Marbach will also produce high-precision steel rule dies for cold cut packaging. In the food industry these are mainly used for sliced sausage and cheese.

For cold cut applications, the complete packaging process takes place in one machine: first the packaging is thermoformed from a plastic film, then the product is inserted and the packaging is sealed by a cover film. The cutting of the packaging is also carried out in the same processing machine and is accomplished in two steps. First, the packaging is die-cut at right angles to the film and then a longitudinal cut is made. A special tool is used for cross-cutting.

Philipp Rüger, R&D Engineer Marbach Werkzeugbau: "This is where Marbach enters play. Recently, we started to produce cutting-dies which have been especially designed for cold cut packaging applications. All Marbach steel rule dies are equipped with the special msilver cutting rule. This coated cutting rule is extremely sharp and very pressure-resistant, it ensures long tool life and maximum productivity for cold cut packaging applications. And should the cutting performance of the knife be reduced, our solution makes it possible to exchange the knife very quickly, easily and, compared to full steel tools, at low cost.

The Marbach steel rule dies for the cross cutting of cold cuts packaging are now available.