26. November 2019

The specialist for pharmaceutical applications. Marbach with a special range of tools.

Marbach is known for its solutions designed to meet all requirements. For applications in the pharmaceutical sector, Marbach has specific tools in its portfolio that have been specially designed for this field of application.

The requirements in the pharmaceutical sector are diverse. Buzzwords such as precision, hygiene and clean room reveal the essential character of pharmaceutical tools. They are used for active ingredient patches, tablet blisters, surgical accessories, labels or outer packaging for wet patches. All areas in which hygiene and precision are vitally important.

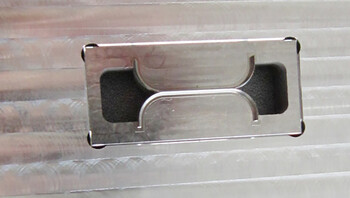

Uwe Murrweiss, Production Manager at Marbach: "For the pharmaceutical sector, we offer tools with solid steel parts, wire-eroded dieboards or PMMA tools, depending on requirements. All tool types possess advantages and are utilized depending on customer requirements. If necessary, several technologies can be combined. For maximum performance in the production of medical products."

Marbach has an internal metal processing department with its own tool shop. Machining techniques such as milling, eroding, coordinate grinding and round processing can be carried out quickly and flexibly.

Compared to conventional rotary or fully milled tools, Marbach special tools are characterized by fast delivery times and hygiene. Marbach's solutions are also unbeatable in price when directly compared.

Another advantage: Marbach has extensive know-how in pharmaceutical tools. For example, Marbach uses special measuring methods to calculate the correct active ingredient area for active ingredient patches and so can manufacture the tool in exactly the right size. Marbach can measure the tools produced, optimize them and use, if necessary, die-cut samples with the customer's own material. This ensures that customers receive their tools in perfect condition and ready-to-use. Very quick sampling is also possible at Marbach.

Murrweiss continues: "An additional advantage of our tools for the customer is that they are very durable. Knives can be exchanged several times and revisions can be carried out quickly and reliably. This is usually the optimal solution for our customers, as a complete validation of a new tool would otherwise be necessary, which is both time-consuming and costly. With a reworked tool, this complete validation is no longer necessary and a short inspection is adequate."

The Marbach-Pharma tools are manufactured by the technical specialists of the Heilbronn-based die-manufacturer.