12. December 2019

pure edge on the road to success. Marbach technology establishes itself.

With its pure edge technology Marbach ensures packaging manufacturers and brand owners are fully satisfied. They have recognized the advantages of this Marbach technology and are increasingly opting for pure edge.

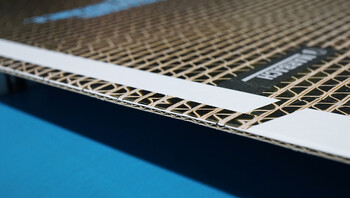

Corrugated board packaging with beautiful visible edges

Marketing Manager Tina Dost: "Brand owners want attractive corrugated board packaging with pure visible edges for sales-boosting presentations of their products at the point of sale. When conventional cutting-dies are used, there is often lint-forming and angel hair on the visible edges. This, of course, is an absolute no-go for products that depend on the attractiveness of the packaging." With pure edge, the requirements of brand owners are fully met, marks and linting are now a thing of the past.

Durable and efficient tools

But it is not only brand owners who are very satisfied with packaging produced using pure edge technology. Packaging manufacturers also benefit from the advantages of this Marbach technology. With pure edge, the conventional functional rubber along cutting rules has been replaced by steel pressers. As a result, the corrugated board is now completely compressed directly next to the knife during the die-cutting process. This ensures very low wear and tear during the die-cutting process. Long service life of the tool is thus ensured.

Dost continues: "The advantages for packaging manufacturers are obvious: consistent results over a very long period of time, no waste and no downtimes. Pure edge stands for efficiency and high packaging quality.