24. July 2017

Marbach nick grinders. For perfect fitting transport nicks.

Marbach not only delivers cutting-dies, but also materials and tools for print shops.

Nicks ensure a smooth transport of sheets through the die-cutting machine. They should however distract as little as possible from the appearance. That’s why packaging producers always try to have as few and small nicks as possible. Nicks play an even greater role in producing a packaging blank. Because transport nicks affect the performance of the production process. And as a result machine speeds. Waste nicks are largely responsible for the waste-free quality of the produced blank.

Marbach developer Sascha Wormser: “Transport nicks should ideally be grinded by the die-maker during the cutting-die production. Also, there are automatic nick grinders available at Marbach, for regrinding on-site.”

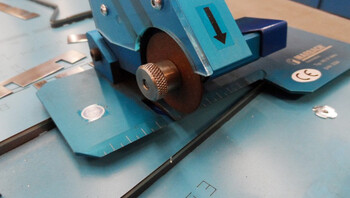

And exactly these nick grinders are available at Marbach. The portfolio contains five different nick grinders. The sales numbers at Marbach speak for themselves. Sandra Hemberger from the Sales department at Marbach Automation & Service: “Our absolute top-sellers are the mafix (pneumatic or with electrical power) and the NG31 AKKU (with rechargeable battery). All three are characterized by their simple handling and their excellent grinding quality.”

The pneumatic functioning mafix L is an in-house development of Marbach. It is used for paperboard cutting-dies. Nicks between 0.2 and 0.3 mm can be precisely grinded with it. It is light and very easy to operate and handle. With a speedy change of grinding wheels, the nick thickness can be adapted to the particular requirements in next to no time.

The NG31 AKKU is another Marbach top-seller. It allows a precise grinding of nicks between 0.2 and 3.0 mm. Through its rechargeable battery it is also location-independent and therefore provides highest flexibility. Its anti-clockwise rotation of grinding wheels directs the flying sparks away from the operator. Its stable grip provides maximum security. The ergonomic handle ensures easy handling. The NG31 AKKU is equipped with a measuring scale and a depth adjustment, in order to achieve best grinding results. With long-life diamond grinding wheels this equipment permits low operation costs.

Sandra Hemberger: “With our nick grinders for grinding transport nicks our customers are well equipped. Additionally, a hand-held tool is currently in development that will be able to place waste nicks quickly and easily. Our customers can already look forward to this.”