19. September 2016

Nick-breaking. Perfect blanking of small cards.

Nick-breaking. A new technology. That allows blanking without problems. For small cards with a double knife.

Jan Brunner, Head of Business Development at Marbach: “Small blanks with double knife in both directions often cause problems. The cards twist during the blanking process. Or tilt. Simply because they are too short or too narrow. That’s why they can’t drop without twisting. This happens on a regular basis. In die-cutting credit cards. Packaging for tooth brushes. Or eyeliner. With our nick-breaking technology, we have a simple and uncomplicated solution for this problem. So we provide our customers with the best performance in the blanking process.”

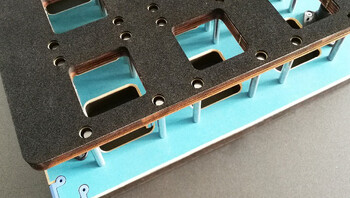

In our nick-breaking tools, the punches in the male blanker are replaced by special pins. These are positioned in a way that the nicks can be separated specifically and in a controlled manner. So the ups fall down vertically. Without twisting. Or tilting. This allows significantly faster machine speeds in special application scenarios with small cards. Without time-consuming machine stops. The blanks can be separated securely. And stacked neatly.