MDSA

14. August 2020

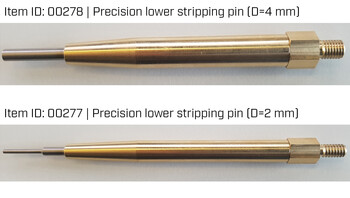

Best performance in the stripping process. New precision lower pins from Marbach Die Supplies.

Marbach Die Supplies has extended its portfolio. Up to now, Marbach has only offered conventional lower pins for the stripping process. As of now, Marbach will also supply its new, self-developed precision lower pin.

André Angermeir, Sales Manager Marbach Die Supplies: "To make the stripping process during packaging production stable and safe, lower pins are used. They fix the waste to be stripped during the stripping process, and ensure that it is guided downwards in a controlled manner. Worn components and greater tolerances of previously available lower pins, can interfere with the stripping process and lead to production interruptions during packaging production. But not with our new precision lower pins. They are made of top quality materials possessing high precision and able to be accurately positioned due to their narrow guide tolerances. A re-adjustment in the die-cutting machine is therefore not necessary."

Thus, the Marbach precision lower pins support a stripping process free of disturbances and waste. They are available in thicknesses of 2 mm and 4 mm.