24. August 2017

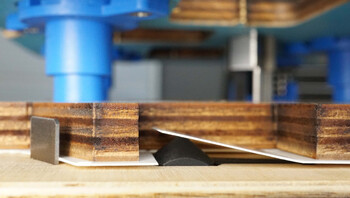

Marbach stripping technology masterstrip|plate. Great for opening up the flaps of cigarette boxes.

The masterstrip|plate is not only a powerful tool for high-speed dynamic stripping. It is also the perfect solution for making sure the side flaps in a cigarette box are cut through and opened up 100%.

Marbach sales director international, Bernhard Reisser: “Already more than half of our stripping tools are in masterstrip|plate design. The sheet can be optimally positioned and fixed to the tool during the stripping process, through a build-in presser plate in the male stripper. The female stripper is equipped with the sheet lifter marbafly. This results in a very stable stripping process and allows very high machine speeds, waste-free and best stripping performance. Also for difficult requirements.”

The option of pre-breaking flaps, that can be integrated into the masterstrip|plate, is used in the cigarette packaging area of application.

Reisser continues: “This additional option ensures perfectly opened flaps. And a smooth packaging process.”

With conventional techniques, automatic pre-breaking of flaps with the male stripper or blanker was often an uncertain process that could lead to interruptions during the production flow. Pre-breaking of flaps has become a safe automated process with the Marbach technology masterstrip|plate.