19. February 2018

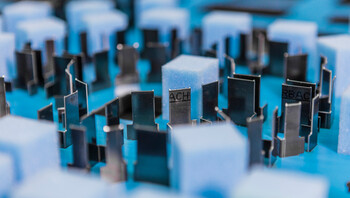

Highest productivity in die-cutting packaging. Packaging manufacturers increase their efficiency with Marbach technologies.

Marbach is known for its innovative strength. And for delivering maximum performance to its customers. Numerous customers of the cutting-die manufacturer have now confirmed that this is not just an advertising statement.

Marco Gieteling, Plant Manager at PilloPak b.v.: "Some time ago, we equipped all our die-cutting machines with digital zone levelling. We use the Marbach greenplate in combination with the mpower|+ technology as our tool of choice. 100 % of the nicks are grounded in by Marbach. Since using these innovations from Marbach, we have been able to increase our productivity significantly. This is because we were able to reduce the set-up time of the knives by 90 %. In addition, the mpower|+ cutting rule is extremely reliable despite very long runs and weekly set-ups. We use marbastrip in the stripping process. So that the placing of lower pins is for us a thing of the past. We are very pleased with Marbach's tools and look forward to further new developments that will enhance our productivity."

Dick van Aarst, Head of Preparation and CAD Operator at Schut-Packaging b.v.: "We are very satisfied with Marbach as our supplier. After all, Marbach never remains on the spot, but constantly develops its products further. This benefits us as a customer. For example, by equipping our machines with digital zone levelling and by using greenplate tools in combination with mpower|s cutting rules, we have significantly reduced our knife make-ready times. More than 90%. This means that we can make much better use of our man and machine capacities than with conventional tools." For blanking we use the lightblanker from Marbach, which has completely convinced us with its easy handling. Many thanks to Marbach for the great technologies that not only make us more productive, but also make our daily lives easier."

Marbach is more than pleased with the positive response and will undoubtedly present further news from its innovation department in 2018.