8. August 2017

Flexibility in blanking. Marbach counts on the marbapusher|p.

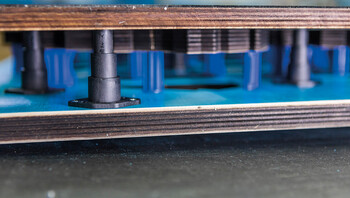

Marbach introduced its optimized blanking technology at the beginning of the year. Since then all upper marbablankers from Marbach are equipped with the new long-life component marbapusher|p. As a result customers are very pleased with the increased flexibility and productivity in their blanking process.

Earlier this year, Marbach re-defined its standard for blanking tools. In doing so, it changed to the presser system marbapusher|p. With huge success, reports Jan Brunner, Head of the Business Development department at Marbach: “The biggest advantage of the marbapusher|p is its special construction. Because with it, we can build a cost-efficient presser plate for every kind of frame. Since using a presser plate is the best way to fix the waste grid, the machine can therefore run at higher speeds.”

Another advantage of the marbapusher|p: the blanking tools allow more efficiency in space-saving because the pushers don’t stand out on the back.

Brunner continues: “Our customers are happy with the new standard. They report to us significantly faster machine performance than with conventional pushers and they achieve a major increase in productivity of their blanking process.”

The marbapusher|p is available exclusively from Marbach.