31. October 2018

Successful appearance at the Scanpack in Gothenburg. Marbach presented its innovations.

Marbach presented its innovations at the Scanpack in Gothenburg between the 23rd and 26th October. Scanpack takes place every 3 years and is one of the most important packaging fairs in Scandinavia.

Gudrun Bertleff, who is responsible for our Scandinavian customers: "Scanpack is a very important trade fair for us, as we have the opportunity to meet our Scandinavian customers in person during the four days of the trade fair. This year, too, we had more than 100 contacts and were able to hold exciting discussions. New contacts and projects have also resulted from the fair, which we will of course promptly follow up."

At Scanpack, Marbach presented its innovations in the fields of die-cutting, stripping and blanking.

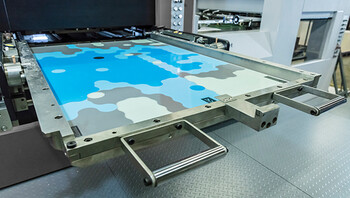

Digital zone levelling.

Digital zone levelling compensates for unevenness in the machine. It ensures that conventional area make-ready, which previously had to be carried out for every job, is no longer necessary. Once a digital zone levelling has been set up, it lasts for months. The result: significantly reduced make-ready times for each individual job. It is available in two versions: DZL|plate for small-format and DZL|foil for large-format die-cutting machines.

Height-adjustable anvil

Reverse cutting technology is used to create elegant tear-open mechanisms in packaging. Highest precision is essential. This is because the paperboard is scored from both sides - from inside and out. With the height-adjustable anvil from Marbach, customers can not only count on optimally functioning opening mechanisms, but also save make-ready time and achieve consistent results.

lightblanker

The lightblanker is a modular blanking tool. Its special feature: The base frame can remain in the machine. It is adapted to the order-related separation mask every time. Thanks to its quick-lock system, the lightblanker is ready for use in a few simple steps. Its advantages: the one-man handling system as well as its high flexibility and fast conversion to sheet delivery.

Marbach thinplate

In the field of hot foil stamping, with the thinplate technology, Marbach has the possibility to archive embossing plates for repeat jobs. This means that they do not have to be newly set-up each time. This saves customers set-up time for repeat jobs.

New service packages.

But Marbach not only had new products on board. In addition to packaging development, Marbach offers packaging optimization and the creation of CAD data according to samples as a service. Marbach can also undertake the cutting of samples and small series for its customers. The advantage: Marbach can directly check the tool implementation during the development of packaging or the creation of data. A big advantage for the customers. Both from a time and cost point of view.

Since 2018 Marbach has been offering training courses on all aspects of die-cutting at the Marbach Academy. Since then, more than 100 people from the fields of paperboard, corrugated board and cigarette packaging have undergone training. The feedback from the participants is consistently positive. Due to the strong practical orientation of the training courses, the participants can immediately put what they have learned into practice in their daily work. Thus Marbach supports the increase of their customers' performance with this service.

Bertleff is satisfied with Scanpack: "The fair was a complete success. We are delighted that our innovations and services were so well received by our Scandinavian customers."