18. March 2019

Efficient blanking. With solutions from Marbach.

Marbach has different solutions for the blanking process in its portfolio: the compact blanker, marbablanker and lightblanker. The latter two have quietly become the industry standard in recent years.

Automatic blanking is fully in trend. Compared to manual blank separation, it brings increased productivity to the entire postpress sector. In addition, it ensures precise stacking of blanks or paperboard sheets. These advantages mean an existing blanking unit in a machine should be used as often as possible. Even for short runs. This increases the efficiency of the further processing of packaging. It saves the operator time and as a result costs for the packaging manufacturer. In addition, it prevents possible health issues for the machine operators, as the physical work required to separate the blanks by hand becomes obsolete.

Sales Manager Bernhard Reisser: "For blanking, we work with a modular system similar to that used in the automotive industry. This means that our solutions are quickly available and we can respond very flexibly to customer expectations. Our systems are all ready-to-use, so that they can be easily and quickly installed in the blanking station. Without long set-up times. We offer a wide range of solutions. Depending on our customer's needs and technical requirements."

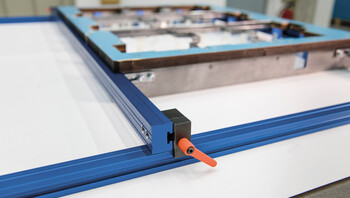

The Marbach lightblanker.

The lightblanker is a modular blanking tool. Its advantage: the base frame can remain in the machine. It can be quickly and easily adapted to the order-specific separating form for any application. Due to its quick-lock system, it is ready for use in just a few simple steps. Reisser: "Since the introduction of the Marbach lightblanker, our customers have increasingly relied on automatic blanking, even for small runs and simple layouts. In 2014, our customers did this in only 5% of cases, today in more than 30%. In other words, the rate of automatic blanking compared to manual blanking has risen sharply for short runs and simple layouts. And the strong upward trend continues."

The marbablanker.

For frequent repeat orders, Marbach recommends the marbablanker to its customers. The marbablanker is individually tailored to the customer's needs and is distinguished by its low weight and high stability compared to a comparable tool in full steel design. Since the tool frame is individually designed for each order and firmly attached to the actual separating form, the marbablanker ensures short set-up times.

Reisser continues: "With our different technologies for the blanking station, we can offer the right solution for every requirement. Providing maximum flexibility for our customers".

Marbach experts are ready to assist their customers in the choice of an appropriate blanking tool with advice and practical help.