die-cutting technology

14. December 2023

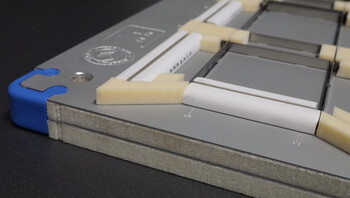

Langlebig, präzise und gleichzeitig leicht. Stanzwerkzeug duramar|alu.

We have launched our dimensionally stable cutting-die duramar|performance under the name duramar|alu, it is now also available in an aluminum version. This new tool in lightweight construction combines many technical advantages with significantly reduced weight and thus supports optimised handling in packaging production.

In the production of packaging, wood is normally used as dieboard material for standard requirements. For higher demands on durability and accuracy in die-cutting, there are dimensionally stable dieboards available. The selection of their materials and their structure ensure that they remain dimensionally stable even under hygroscopic influences and strong climatic fluctuations. In the past, our flagship and high-end tool was the duramar|performance dieboard. Now we are setting new standards with our cutting-die duramar|alu.

duramar|alu is a tool whose dieboard combines glass-fiber strengthened plastic with aluminum sheets. This not only ensures maximum dimensional stability – even under changing climatic conditions – but also substantially less weight.

Industry manager Bernhard Reisser: "Our new duramar|alu tool has outstanding technical properties and, thanks to its lightweight construction, is over 30 % lighter than its previous tool in the steel version. The reduced weight of the duramar|alu tool simplifies handling during the set-up process, during in-house transport and when storing the tools. It also reduces the workload of the machine operators in their daily work. But that's not all: savings in transport costs are achieved due to its low weight."

duramar|alu thus combines many advantages in one tool: low weight for optimised handling, maximum dimensional stability, and a precise register for the best creasing results.

More information about the new Marbach dieboard can be found on the Marbach Experience Hub: https://experience.marbach.com/en/blog-detail/durable-precise-and-light-this-is-possible