18. May 2018

The new marbanick|2 by Marbach. For perfect nicks.

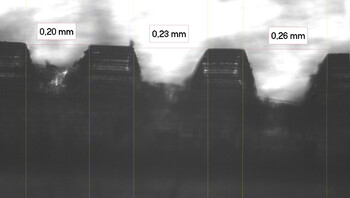

Marbach has recently updated its handheld device for placing nicks into cutting rules. So far, this tool – that is known on the market under the name marbanick – could place a nick with a predefined width and depth into the cutting rule. With the new marbanick|2 version, width and depth of the nicks can now be varied in three steps.

Nicks play a greater role in producing a packaging blank. Because nicks ensure on the one hand a smooth transport of the board sheet through the die-cutting machine, and on the other hand freedom from waste of the produced blank. For packaging producers, it is vital that the packaging has small and as few nicks as possible, because they distract from the appearance of packaging. There are two kinds of nicks: transport nicks which have an impact on the speed of the producing machine. And waste nicks which are largely responsible for the waste-free characteristics of the produced blank.

Marbach developer Sascha Wormser: “Transport nicks should ideally be grinded by the die-maker during the cutting-die production. Also, there are automatic nick grinders available at Marbach, for regrinding on-site. Sometimes it makes sense for our customers to optimize waste nicks directly on the machine – matched to the local conditions. Especially for this kind of case, we have developed the new marbanick|2. Because with it our customers can place three different thicknesses of nicks into their cutting rules. So that nicks can be optimally adapted to local requirements. Placing a nick is very easy, safe and controllable. The cutting rule will not be destroyed in an uncontrolled manner.”

The new marbanick|2 has not only been equipped with three levels, but also importance has been attached to good handling and achieving the best ergonomic characteristics. So the follow-up model is not only better, but also easier to handle than its predecessor.