24. November 2016

Blanking efficiency. Efficiency counts.

Automatic blanking is trending. The advantage is not just productivity. But also an exact delivery of the blanks. For optimal processing. Marbach, worldmarket leader in cutting-die manufacturing, has completely reworked its blanking technologies this year.

The results are the two new blanking tools: lightblanker and marbablanker. The lightblanker is characterized by its light weight and cost-efficient design. This tool is perfect for orders that have previously been separated manually. For higher requirements, Marbach has developed the marbablanker. The advantages: it is perfectly tailored to the operator’s requirements and therefore allows a smooth production process. For very small blanks, Marbach has introduced the new special solution nick-breaking.

The light way of Blanking. The lightblanker.

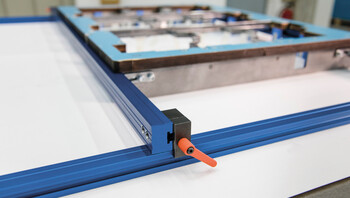

The lightblanker is a modular blanking tool. Its advantage: the base frame can stay in the machine. It gets adjusted each time according to the job-specific blanking grid. Ultra fast. A few quick steps and the lightblanker is ready to use. With quick lock functions. Eduard Görtz, Marbach blanking expert: “The light weight tool will win you over with its one-person handling and high flexibility. Also with the easy conversion to sheet delivery. Compare manual blanking with the lightblanker. You will see – it's worth it.”

Simply efficient. The marbablanker.

The marbablanker makes blank separation child’s play. It has been perfectly developed for the customers’ needs. The blanking process is fast and trouble-free. Görtz explains: “Our customers choose from different options. They have an unbelievable variety. And also an unbelievable efficiency.” Blanking has never been this easy, so light, so stable and economical all at the same time.

Perfect blanking of small cards. With nick-breaking.

Blanking small cards with double knife – such as blister cards and creditcard formats among others – often cause problems.

That’s why Marbach has invented nick-breaking. Görtz: “With our nick-breaking tools, the punches in the male blanker are replaced by special pins. These are positioned in a way that the nicks can be separated in a focused and controlled manner. So the ups fall down vertically. Without twisting. Or tilting.” This allows significantly faster machine speeds in special application scenarios with small cards. Without time-consuming machine stops. The blanks can be separated securely. And stacked neatly.

Marbach has widened its blanking tool range significantly. And can now offer its customers the perfectly fitting tool for every requirement. For small quantities. And large ones. For simple layouts. And difficult ones. For automatic blanking, that’s worth it.