MDSA

die-cutting technology

12. May 2020

Marbach mhard|r+. A new era in rotary cutting rules.

Marbach Die Supplies & Automation (MDS&A) has become one of the major cutting-die material distributors in Germany. With its new rotary cutting rule for corrugated board, the mhard|r+, Marbach has launched a rule that is very robust and ensures best cutting results.

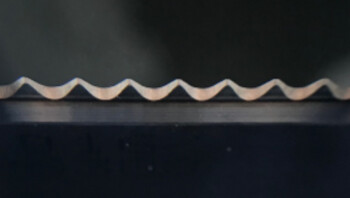

The rotary cutting rule mhard|r+ stands for a new generation of rotary cutting rules for die-cutting of corrugated board. Due to its unique knife hardening and its special serrated edge technology it effortlessly inserts into the corrugated board to be die-cut. The result is a very smooth cutting result of the packaging blank, even with high grammages and heavy corrugated board.

Ingo Graham, Product Manager at Marbach: "Due to its many positive features, some of our customers already use the mhard|r+ as the standard cutting rule for all corrugated board to be die-cut. Because of its small teeth depth the mhard|r+ protects the counter part and thus ensures less wear. Special hardening of the cutting edge means it is not only very durable but also very stable. This makes it ideal for use in areas of high stress such as narrow bending angles, diagonal lines and circular die-cutting. The special serrated grinding technology requires a lower cutting pressure. This not only protects the rule and the counter layer, but also ensures reduced dust formation and exceptional cutting results of the packaging blank."

The rotary cutting rule mhard|r+ is now available at Marbach Die Supplies.