die-cutting technology

24. May 2022

The right solution for every requirement. The stripping technologies from Marbach.

We are known for our tailored solutions. Also for the stripping process in packaging production, we offer different die technologies which can be selected individually according to your requirements.

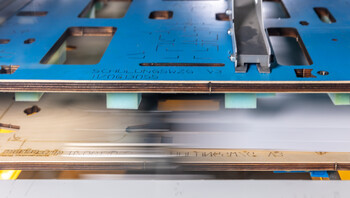

Conventional stripping with lower pins is very time-consuming and at high speeds, offers limited functionality. Therefore, running under the name "dynamic stripping", Marbach offers different tools, marbastrip and masterstrip|plate which do not require any lower pins at all.

The standard: marbastrip stripping tool

With marbastrip technology, the time-consuming setting of lower pins is no longer necessary. Thanks to its special design, this tool ensures a stable stripping process. Special stripping claws securely fix the waste parts and guide them through the parting line. marbastrip is ready for immediate use and ensures an efficient set-up and stripping process. With marbastrip, Marbach has created a standard that has been in use worldwide for decades.

For top performance: The masterstrip|plate stripping tool

Based on the marbastrip technology, we have developed the high-performance tool masterstrip|plate. The male stripper of the masterstrip|plate is equipped with a presser plate. This smoothes the paperboard sheet and thus ensures a perfect register between sheet and stripping tool. Special sheet lifters in the female stripper (marbafly) support the smooth onward transport of the paperboard sheet. The optional marbapoint set-up aid can be included as well. Its laser ensures that the male and female stripper parts are positioned in the die-cutting machine quickly, easily, and in line with each other. All in all, this results in a smoothly operating system that stands for top performance in stripping.

Industry manager Reisser: "The marbastrip and masterstrip|plate tool solutions are perfect for a wide range of applications. But when things get really tricky, especially in jobs where a lot of filigree waste has to be stripped, then special solutions are needed. But where the requirements for waste-free die-cut blanks are extremely high, even the marbastrip and masterstrip|plate technologies can reach their limits. In such cases, we recommend a lower pin unit equipped with special precision lower pins. These can be positioned individually and precisely, so that waste-free processing can be ensured even with small waste parts."

The selection of the appropriate stripping technology always depends on the requirements of the particular job.