die-cutting technology

4. March 2021

Quick and easy storage of die-cut paperboard sheets. How the universal sheet delivery makes everyday work easier.

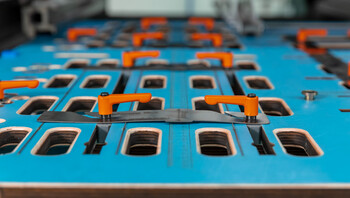

For more than a year Marbach has had a tool in its portfolio that is used whenever customers do not want to use blanking for a job, but still value efficiency. The so-called universal sheet delivery is used in the upper part of a blanking station to perfectly stack die-cut sheets.

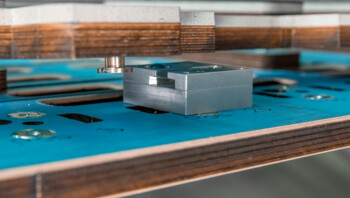

Marbach Sales Manager Die Cutting Technology, Jan Brunner: "The sheet delivery in the blanking station of a die-cutting machine can be upgraded with our technology. In this way the full sheet delivery can be quickly and easily adapted to each individual job, and without lengthy set-up times. Compared to conventional solutions, this makes conversion from blanking to sheet delivery and vice versa both very fast and very efficient. However, the time aspect in the die-cutting process is not the only major advantage of the universal sheet delivery. The precise stacking of the paperboard sheets ensures smooth further processing in the folder gluer."

The universal sheet delivery is available in 102-106 format and 142-145 format. It is suitable for both jobs with both single and double knife, which means it can also be used in the pharmaceutical and tobacco sectors.

Brunner continues: "Customers who are already using the universal sheet delivery say it makes their work easier. They are convinced by its easy handling, the short make-ready times and the running properties of the cutting-die when used on the die-cutting machine. Some of our customers also report higher speeds that can be achieved with the universal sheet delivery compared to conventional systems, because the sheet delivery functions more reliably and with less disruption."

In the lower section, the lightblank base frame, supplemented by a job-specific frame, is the perfect counterpart to the universal sheet delivery. If required, it can be combined with a guillotine for separating gripper edge waste.