17. May 2017

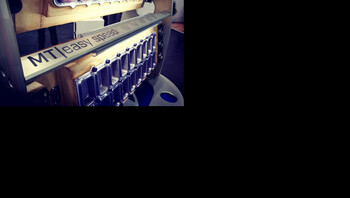

Match-metal technology for high speed.

Marbach introduced its innovation MT|easy speed at the K 2016. Since then various customers have switched to this technology. And they are delighted by the performance they achieve with MT|easy speed.

One of those convinced customers is The Thrace Group, which is the largest manufacturer of thermoformed products in Greece.

Production manager of thermoforming, Stathis Ioannis, reports his experiences with the new Marbach technology: “We have been using MT|easy speed tools for 3 months already. Our experiences have been entirely positive. The tool handling is remarkably simple, the make-ready times are short. And the retrofitting from one tool to the next one is noticeably faster than with conventional thermoforming tools. This is achieved by a quick-change system with which the MT|easy speed tools are equipped.

What we have noticed during the last months: the efficiency of Marbach MT|easy speed tools is significantly greater than the tools of Marbach competitors which we have used up to now. We can report a performance increase of more than 10% in comparison. Overall, the production process is more stable. Moreover the cooling of the thermoforming tool is more efficient so our energy consumption has been reduced through the use of MT|easy speed tools.

And the best of all: we not only have advantages with regard to productivity but also concerning the quality of the end product. With MT|easy speed the material distribution is exceptionally good. So the wall thickness of the thermoformed products is very consistent. For this reason the quality of our final products has been significantly improved.”

The Thrace Group will also rely on MT|easy speed by Marbach in the future. As many other customers, who have tested this new Marbach technology.