27. March 2018

Marbach at the Expoprint in São Paulo. Successful appearance in Latin America.

Marbach presented its latest developments at the Expoprint in São Paulo (Brazil) from 20th to 24th March. Visitors were very curious about the solutions Marbach could offer for highest performance in die-cutting for packaging.

The Expoprint, which takes place every 4 years, is a major paper and printing trade fair in Brazil. Marbach was a co-exhibitor at the VDMA (Association of German Machine Manufacturers). At its 12 m² stand, the Heilbronn-based die-maker presented its innovative highlights from the past months.

Marketing Manager Tina Dost: "We had a wide range of products to showcase which met with great interest. Visitors were enthusiastic about the possibilities offered by the Marbach technologies. Especially with regard to performance and packaging finishing. Our visitor magnets were the height-adjustable anvil, our finishing techniques and the blanking technology marbablanker."

Height-adjustable anvil

The reverse cutting technology is used to produce elegant opening mechanisms in packaging. Highest precision is essential. In reverse cutting, the paperboard is scored from both sides - inside and outside. With the height-adjustable anvil from Marbach, customers can not only count on optimally functioning opening mechanisms, but also save make-ready time and achieve consistent results.

Refinement

Marketing manager Tina Dost: "There are many possibilities to refine packaging and enhance it for the POS. Embossing in 2D or 3D, hot foil embossing, pure edge or reverse cutting. In addition, high-quality creases or multiple creases close to each other make a packaging something very special. With our tools and our special technologies, we offer our customers the right solution for every requirement. For extraordinary packaging at the POS that is not only an optical but also a tactile experience for the consumer."

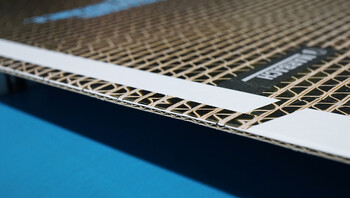

pure edge

With this Marbach-developed technology, the rubbering effect along the cutting rules is replaced by steel pressers. As a result, the corrugated board is completely compressed during the die-cutting process right next to the knife. This results in very clean cuts, the formation of cutting dust and the development of angel hair is thus prevented.

marbablanker

The marbablanker is a light but stable blanking tool that is perfectly adapted to the customer's needs. The marbablanker is characterized by a fast and smooth blanking process and at a reasonable price.

Dost continues: "The Expoprint in São Paulo has been a very interesting trade fair with many exciting conversations for us. We will definitely be back in four years."