25. January 2017

Improvement of machine performance. Digital zone levelling

Marbach, launched its digital zone levelling technology at drupa 2016. The product’s success was almost immediate: half a year later, over 100 die-cutting machines worldwide have been equipped with digital zone levelling. A strongly increasing trend. Marbach offers its product currently in 76, 102-106 and 142-145 format. More are already planned.

But what can this product do? Jan Brunner, Head of Marbach Business Development: “Digital zone levelling, levels out the height deviations of the cutting platen. So now there’s no need for any conventional area patching that previously had to be made for every single job. Once a digital zone levelling is set up, it lasts for months. And provides best die-cutting performance and short make-ready times for the operator.”

The customers that already work with digital zone levelling are excited. From international manufacturers for folding boxes through trade finishers to family-owned companies. They have all realized the advantages the Marbach product implies. Many started with one machine. And equipped further machines on the basis of those test results.

A leading German manufacturer of folding boxes uses digital zone levelling already in different plants: “We are happy with this product. Time-consuming patching, that we had to execute for every single job, is no longer necessary. And that is why our productivity has increased enormously.”

Digital zone levelling has also convinced a traditional family-owned US based company: “We can patch-up less with the new vetronite plate from Marbach. And the handling is super easy for us.”

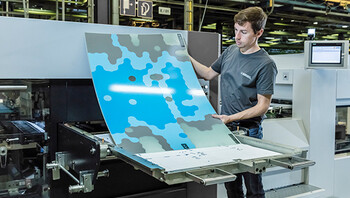

How does digital zone levelling work? The operator makes an impression of the machine using a standardized procedure. Marbach then creates a new, modified cover plate for the make-ready sheet. Individually made for this machine. This levels out the height deviations of the cutting platen. So manual area patching of every single tool isn't necessary. Digital zone levelling ensures, together with the Marbach innovations magic sheet and mpower|+ die-cutting, next to no patching-up. For highest performance in packaging production.